In a time defined by rapid change, increased uncertainty, and growing operational complexity and regulation, it is no longer enough to solve problems when they appear – you must detect them early, understand why they occur, and prevent them from happening again. This is precisely why deviation management has become one of the most important building blocks in modern quality and risk management.

Without a structured process for handling deviations, organizations risk missing critical information, repeating the same mistakes over and over, and losing time, money, and trust. In this article, we explore deviation management – what it is, why it matters, how it connects to risk management, and how today’s smart system support can make the work easier.

What is Deviation Management?

Deviation management – or deviation reporting, as it is sometimes called – is exactly what it sounds like: managing deviations. It refers to a structured process for identifying, documenting, analyzing, and addressing events that do not align with established procedures or standards. The purpose of deviation management is to enable continuous improvement, prevent errors, and strengthen quality within the organization.

What is a Deviation?

There are many types of deviations, which can vary greatly depending on the industry. A deviation can be anything from a broken workflow or incorrect documentation to a production quality issue or non-compliance with standards such as ISO 9001 or HACCP. Here are some concrete examples from regulated industries:

Deviations in the Healthcare Sector

Example: A patient receives the wrong dose of medication because the prescription list was not updated in the medical record system. The error is discovered by the nurse during the next medication round.

Type of deviation: Medical deviation / patient safety deviation

Why it matters: Incorrect medication can cause serious harm and is among the most frequently reported deviations in healthcare.

Deviations in the Transport Sector

Example: A driver loads cargo without applying the proper load securing required by current procedures. At the end of the transport, it is discovered that the cargo has shifted, posing potential danger to both the driver and other road users.

Type of deviation: Safety deviation / procedural deviation

Why it matters: Improper load securing is one of the biggest risk factors in transport and can lead to accidents, injuries, and financial losses.

Deviation in the Food Industry

Example: During a routine internal inspection, it is discovered that the temperature in a cold-storage room is above the critical limit for safe storage of raw materials. The temperature deviation has been ongoing for several hours.

Type of deviation: HACCP deviation / food safety deviation

Why it matters: Excessive temperatures can lead to bacterial growth and pose a risk of unsafe food reaching consumers — a critical issue in food safety.

Why Is Deviation Management Important?

Deviation management is essential for organizations to operate safely, efficiently, and sustainably. When deviations are identified, reported, and analyzed in a structured way, they become an invaluable source of learning. Every deviation – big or small – provides insight into where processes fail, where procedures do not work in practice, and where risks are not properly controlled.

Without an effective deviation management process, the organization risks repeating the same mistakes, resulting in unnecessary costs, quality issues, safety risks, and – in the worst case – harm to people, the environment, or the brand.

A systematic approach allows the organization to prevent recurring problems, strengthen its quality, improve traceability, and create a culture of continuous improvement. Deviation management should therefore not be viewed merely as an administrative task – but as a central component of building a successful organization.

What Is the Difference Between Deviation Management and Risk Management – and How Do They Relate?

Deviation management and risk management are both central components of modern quality and management work, but they serve different purposes.

Deviation management deals with events that have already occurred – errors, issues, incidents, or departures from procedures and requirements. The goal is to understand what went wrong, manage the consequences, and implement corrective and preventive actions to prevent recurrence.

Risk management, on the other hand, is forward-looking. It focuses on identifying potential events that could negatively impact the organization before they occur. Risks are analyzed, evaluated, and managed by implementing controls and procedures that reduce probability and impact.

Despite their differences, the two areas are closely connected. A deviation often reveals a risk that has not been adequately managed – and every deviation provides valuable information for future risk assessments. Together, they form a learning cycle that strengthens organizational safety and performance.

Organizations that integrate these approaches create a more robust and predictable operation, where both what has gone wrong and what could go wrong are handled systematically. This is also why managing deviations and risks in the same system offers many advantages.

How a Deviation Management System Can Support the Work

In many organizations, deviation management still takes place in Excel, email, or paper forms, making consistency, traceability, and oversight difficult. Many organizations also try to build deviation processes in tools like SharePoint. This can work for simple cases but often lacks:

- standardized workflows for different case types

- support for root cause analysis

- clear role- and permission control

- full traceability and audit history

- document and process connections

- automated notifications and dashboards

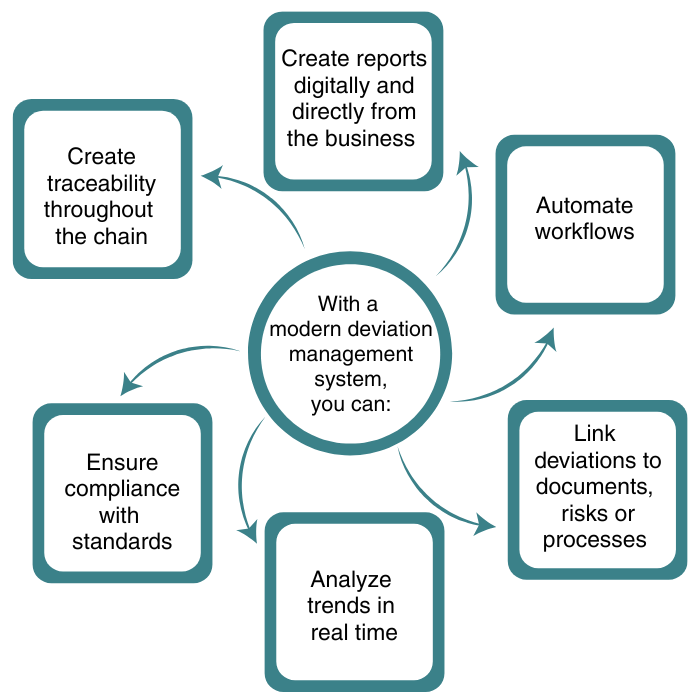

With today’s increasing requirements for compliance, traceability, and safety, many companies choose a dedicated system for deviation management instead. A deviation management system is a digital tool that collects, structures, and automates the entire process of reporting, investigating, correcting, and following up deviations.

Introducing such a system ensures that deviations are captured immediately, the right people are notified automatically, and investigations and actions are documented systematically. The system reduces the risk of forgotten cases and creates a clear workflow that makes it easier for both employees and managers to work systematically. Key benefits include:

- higher quality

- faster handling

- better compliance

- fewer recurring errors

- a more data-driven improvement culture

A good deviation management system is therefore not just an administrative aid – it is a strategic investment in safety, efficiency, and continuous operational development.

Traceable Deviation Management With Centuri

At Centuri, we have extensive experience helping organizations in complex regulated industries strengthen their quality work. Among our customers are organizations within healthcare, transport, food, and life science.

With Centuri, organizations gain a powerful and user-friendly deviation management system where cases, processes, documents, and risks can be gathered in one place. This makes it easy to report deviations, follow up actions, analyze trends, and connect all quality work – from risks and routines to audits and internal controls.

By digitalizing and standardizing workflows, Centuri creates a culture of continuous improvement where no deviation is lost and every insight contributes to a safer and more efficient operation.

Contact us today if you want to learn how you can take your quality work to the next level.

-1.png)